In the high-stakes environment of an operating theatre, impeccable HVAC hygiene is not just a best practice—it is a lifesaving necessity.

The Importance of Rigorous Hygiene Standards in the Operating Theatre

Maintaining rigorous HVAC hygiene standards in the operating theatre prevents infections and ensures patient safety. The sterile environment of an operating theatre demands meticulous cleaning and disinfection to eliminate any potential sources of contamination, and this also needs to include the air conditioning systems serving these critical controlled environments.

Healthcare-associated infections (HAIs) can have severe consequences for patients, including prolonged hospital stays, increased medical costs, and, in severe cases, loss of life. These stark realities underscore the critical need for implementing stringent hygiene protocols to ensure patient care and safety.

What is inside your duct? Snap a picture to find out.

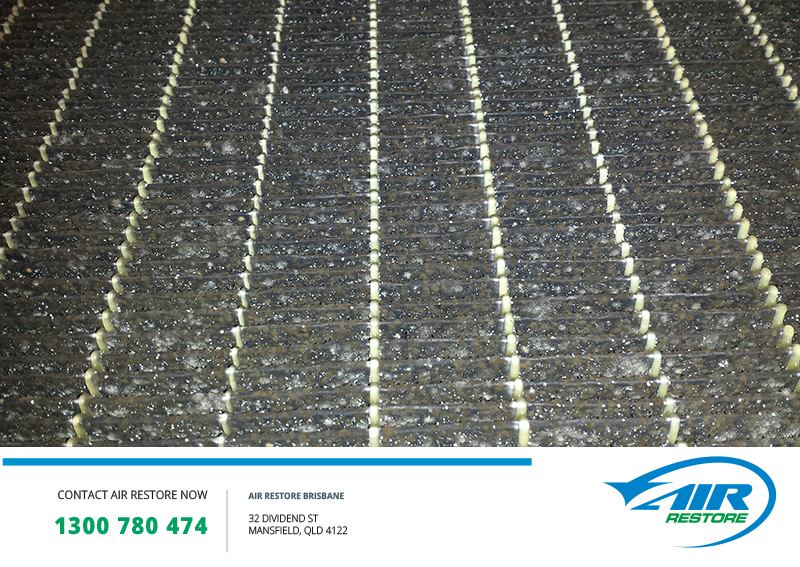

Air ducts in operating theatres are pivotal in maintaining air quality and controlling the spread of pathogens. Over time, these ducts can accumulate dust, debris, and microbial contaminants that compromise the sterile environment. This debris can also affect the integrity of HEPA filters, the last line of defence that protects the patient from air quality risks.

Regular HVAC hygiene audits and cleaning of HVAC air handling and ducting systems are essential. Advanced techniques, such as duct cameras, can capture images of the inside of the ducting, allowing for a thorough assessment and developing a scope of remedial work to restore the system to optimal hygiene level. Clean systems are more energy efficient and assist in maintaining air change rates, pressurisation, and air balance, all essential parameters for effective air quality control in your theatre suite.

HVAC Hygiene and Disinfection Services

Regular HVAC hygiene and disinfection services are a cornerstone of maintaining a safe operating theatre air quality. These services involve thoroughly cleaning the AHU and all internal components, such as coils, fans, drain trays, walls, motors and dampers. The ducting is also cleaned in the airflow direction, starting at the return air grilles and working through the systems to include the return, outside and supply air ducting. All ducting is maintained at negative air pressure using HEPA-filtered negative air machines to prevent cross-contamination of the hospital air quality during cleaning.

Standards, guidelines and Queensland Health Task descriptions

Minimum Standards

The minimum standards for periodic inspection and servicing shall be as stated below and in accordance with the requirements of the current editions:

- AS/NZS 3666.2 Air-handling and water systems of buildings – Microbial control Part 2: Operation and maintenance

- AIRAH HVAC Hygiene; Best practice guidelines

- Queensland Health Centre for Healthcare Related Infection Surveillance and Prevention (CHRISP) program. Visit the website at http://www.health.qld.gov.au/chrisp.

Infection Control Guidelines: Queensland Health’s comprehensive guidelines cover all aspects of infection control, including those relevant to operating theatres. They provide details on standards for surface cleaning, air quality management, and more, all tailored to minimise infection risks in healthcare facilities Queensland Health.

During audits of HVAC systems in operating theatres in Queensland, critical metrics for assessing compliance with cleanliness guidelines typically focus on air quality, the cleanliness of ventilation ducts, and the system’s effectiveness at controlling airborne contaminants.

- Airflow measurements are critical. They ensure that ventilation systems operate at the required airflow rates to maintain appropriate pressure differentials, which helps prevent the spread of contaminants.

- Particulate matter and microbial testing are standard practices. This includes measuring levels of airborne particles by real-time particle counting and verifying the presence of bio-aerosols, which could indicate contamination in the ventilation system or a failure of HEPA filter integrity.

- HEPA Filter integrity and performance are also assessed annually, ensuring that filters are effective at trapping contaminants and have been replaced or maintained per manufacturer guidelines.

- Visual inspections of ducts and vents ensure the system is free from dust, mould, or debris, which could compromise air quality.

How Often Should You Clean Your Operating Theatre HVAC

Service Requirements and Frequency

| Service Item | Required Yearly |

| Visually inspect the air side of each HVAC system, including components such as air handling unit internal walls, condensate trays and drains, HVAC ducting including air outlets, return and exhaust grilles, fans and fan housings, coils, heater banks, humidifiers and air filters. | ✓ |

| Provide a written report, including photographs where possible, to record the current state of the HVAC internal condition. | ✓ |

| NOTE: The report shall detail all problem areas and shall advise if cleaning and decontamination of any component of the HVAC system is necessary. For any identified contamination, the report shall include recommendations on how the possible cause or source of the contamination can be reduced or eliminated. Include timelines and estimated costs of all recommended works and their priority. |

Choosing Air Restore as your HVAC Hygiene Contractor

Air Restore has built a solid reputation for superior HVAC hygiene and is trusted by the Queensland Government with a Standing Offer Arrangement (SOA) for our reliable, high-quality services. We understand the importance of minimising disruptions to your business, so we offer flexible scheduling, working evenings and weekends to suit your needs. With Christmas approaching, now is the perfect time to schedule an HVAC audit or cleaning. Proactively maintaining your systems ensures optimal performance and helps you avoid costly downtime during the busy holiday period. Let us help you keep your indoor environment safe, clean, and efficient.