IL Coil Clean – UV Surface Sterilisation

Why do you need Sanuvox IL CoilClean – UV Air Sterilisation System?

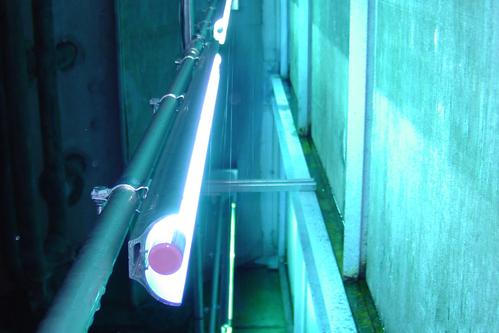

UV Surface sterilisation – preventing bio-film and mould growth on cooling coils and high-risk areas in HVAC ducts.

Condensation, humidity and temperature make cooling coils ideal breeding grounds for mould, fungi and bacteria. As a result, they are often the source of problems with indoor air quality. In addition, when bio-contaminants build upon the surfaces of the coil, they can also restrict airflow and reduce the efficient transfer of heat.

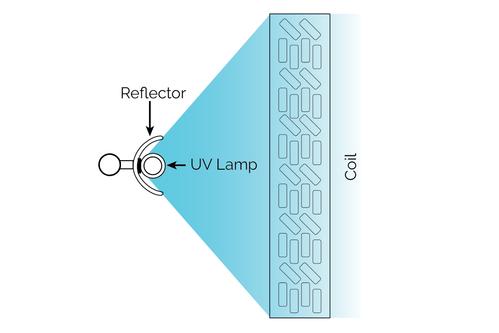

Sanuvox IL CoilClean – UV Air Sterilisation System uses patented technology incorporating high-intensity UVC germicidal lamps and aluminium parabolic reflectors.

Like a car’s headlights, Coil Clean IL uses reflectors to direct light to where it’s most needed. The reflectors, made from lightweight aluminium, means it’s one of the most reflective materials available, maximising UV efficiency and intensity. In addition, the CoilClean IL directs virtually 100% of the UVC energy onto the coil – this maximises the unit’s efficiency and extends product life and protects the lamps against fouling.

To help you choose the correct UV coil cleaning products, Opira can model the UV exposure time and intensity against recommended kill times for specific strains of bacteria, mould, viruses and fungi.

Applications

- Any building equipped with an HVAC system

- IL Coil clean can be installed on either side of the evaporator coils

- Walk-in or ample cooler storage for fruits and vegetables equipped with a cooling system

Benefits

- Uses up to 50% fewer UVC fixtures than the competition

- Provides a 99% disinfection of mould in under 60 minutes

- An aluminium reflector protects the lamp from fouling cooling

- Reduces energy consumption on the HVAC system

- Reduces ethylene build-up to slow ripening of fruits

- Increases the lifespan of fruits and vegetables

- Makes chemical cleaning of coils unnecessary

- Reduces biological load within food storage cooler

We rely on modelling software to calculate the sterilisation requirements based on the coil dimensions, the distance the light is from the coil and the airflow conditions in your building. Request a quote, and we can walk you through all the details.